Brown Engineers from the classes of ’26 and ’27 bridged the gaps between theoretical knowledge and practical application with their 2025 summer internships and research projects. All over the world, Brown Engineers gained unique opportunities to apply classroom concepts to real-world challenges and deepened their understanding of the engineering discipline during the summer break. Beyond technical skills, they developed essential professional competencies, and their work helped shape and re-shape career aspirations.

See how a few of our students spent their summer months:

2025 summer experiences for Brown engineers

Mia Anderson

Mia Anderson

Biomedical Engineering, Class of 2026

Strategy, Development and Innovation Intern,

Becton, Dickinson and Company

Warwick, RI

Alice Cannon

Alice Cannon

Mechanical Engineering, Class of 2026

Noise and Vibration Intern,

Acentech

Cambridge, MA

Patience Gifford

Patience Gifford

Mechanical Engineering, Class of 2027

Applications Intern,

Amphenol

Mesa, AZ

Lauren Hogan

Lauren Hogan

Chemical Engineering, Class of 2027

Chemical Engineering Intern,

Eastman Chemical Co.

Indian Orchard, MA

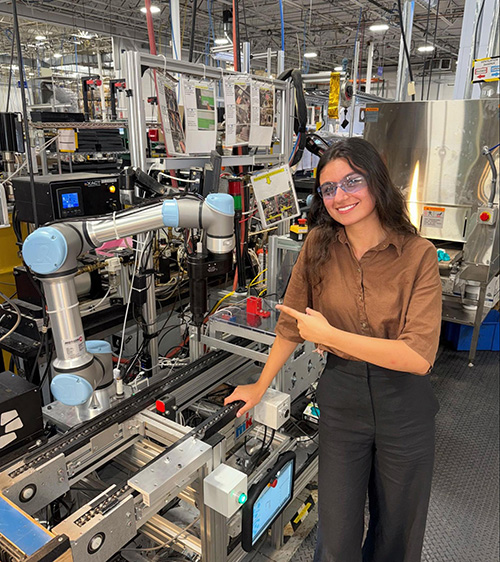

Hania Khan

Hania Khan

Mechanical Engineering, Class of 2027

Mechanical Engineering Intern,

Hayward Holdings

North Kingstown, RI

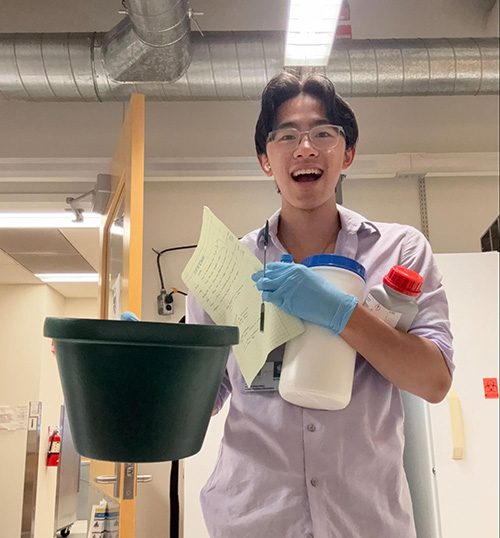

Alex Lim

Alex Lim

Biomedical Engineering, Class of 2027

Intern,

Oregon Health and Science University

Portland, OR

Emilia Pantigoso

Emilia Pantigoso

Biomedical Engineering & Entrepreneurship, Class of 2026

Cardiac Rhythm Management R&D Intern,

Boston Scientific

Arden Hills, MN

Julia Patterson

Julia Patterson

Biomedical Engineering, Class of 2026

Summer Intern Global Clinical Immunology - Vaccine,

Sanofi

Swiftwater, PA

Helen Primis

Helen Primis

Mechanical Engineering, Class of 2027

Mechanical Engineering Intern,

WSP

Arlington, VA

Adrian Velazquez-Martinez

Adrian Velazquez-Martinez

Electrical Engineering & Applied Mathematics, Class of 2026

Electrical Engineering Intern,

Honeywell Aerospace

Phoenix, AZ

Terren Wise

Terren Wise

Design Engineering, Class of 2026

Technical & Regulatory Services Intern,

Nuclear Energy Institute

Washington, DC

Andy Woxland

Andy Woxland

Design Engineering, Class of 2026

Manufacturing Engineering Intern,

Mars Wrigley

Topeka, KS