Manipulating materials

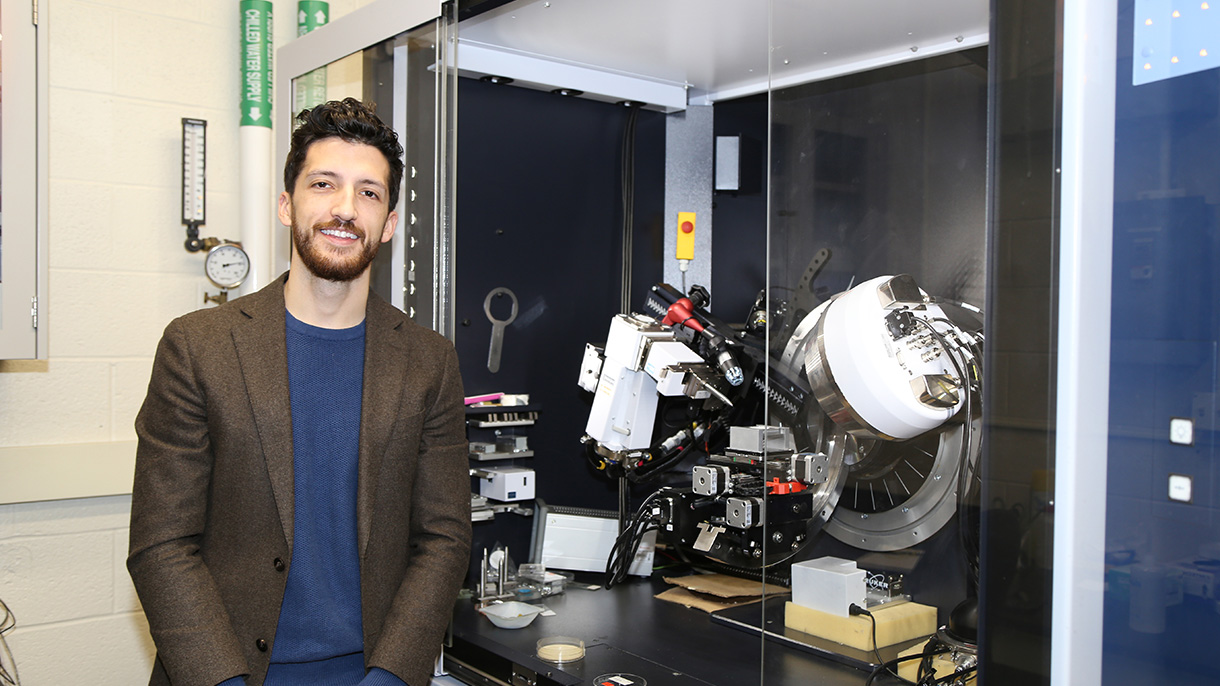

From atoms to devices, Assistant Professor Lucas Caretta aims to synthesize and discover new materials to push research and technology further.

With a purebred materials pedigree, the School of Engineering’s newest assistant professor, Lucas Caretta, has arrived on College Hill. He comes from a postdoc stint at Cal Berkeley, after earning his Ph.D. at MIT. But it was in the Twin Cities of Minnesota where his childhood fueled a passion for STEM.

As the youngest of four children born to parents who put a great value on education, Caretta knew the engineering discipline from a young age. His mother, a special ed paraprofessional in an elementary school, and his father, a chemical engineering professor at the University of Minnesota (UM), both grew up in Argentina and moved to the United States for the opportunities UM offered the young couple. “I’m fortunate to have a father who was a professor and knows how important science and engineering are to the world, to the economy, and to the quality of life,” he said.

As the youngest of four children born to parents who put a great value on education, Caretta knew the engineering discipline from a young age. His mother, a special ed paraprofessional in an elementary school, and his father, a chemical engineering professor at the University of Minnesota (UM), both grew up in Argentina and moved to the United States for the opportunities UM offered the young couple. “I’m fortunate to have a father who was a professor and knows how important science and engineering are to the world, to the economy, and to the quality of life,” he said.

“Some of my fondest memories growing up with my dad were when I was stuck on math homework in middle school. He’d tell me the way they do it in Argentina versus the way they do it in the U.S., so I’d have multiple perspectives on how to do math problems. Plus, he’d give me extra ones to solve. I actually enjoyed that, and I think that’s what got me hooked on math.”

Caretta realized early on that math and science would be the avenues he wanted to pursue, and knew materials engineering at the University of Minnesota would be where he would do so. “Not many high school students, or even college students, know what materials science is, which presents a challenge for a lot of materials departments,” he reflected. “It’s an exciting field. A lot of engineers I’ve spoken with wish they would have studied it, in hindsight. When you talk to seniors or juniors, who are already committed to a major, you find out they didn’t realize what material science was until it was too late to change their major or graduate in a reasonable amount of time.

“The challenge materials engineers now face is how to inject materials science, or at least materials ways of thinking, earlier. Not just in the college curriculum, but in high school as well,” he said, his enthusiasm unfettered. Caretta is passionate about the materials mindset.

“Mechanical engineering, most people know about. Electrical engineering, most people know about. Chemical engineering, most people know about. Even biomedical engineering — which is a newer area than materials science — is more popular than material science right now. So what are we doing wrong, and how can we fix it? The broad challenge is making materials attractive again, and the specific challenge, for me, is making magnets attractive again.

“When people think of materials science, they often think of metals and ceramics, but those tend to not catch the attention of students. They can, but it’s all about how materials scientists pitch them. Mining and metallurgy, for example, are really where materials science has its roots. Consider concepts like the Bessemer process, casting, heat treating, and breaking materials open to investigate them — these are fascinating to someone like me, but maybe not to the average student.

“But we can also teach metallurgy through more tangible examples. For instance, Apple’s Macbook Pro uses a single piece of aluminum with a matte finish and aesthetic design. That’s all materials science. What’s even more interesting is that there are no moving parts in a Macbook. There are no fans to keep it cool. How do you cool a laptop without moving parts? You need passive heat dissipation — heat that goes through this piece of aluminum and gets to the outside world. The problem is to get that finish, that signature look of a Macbook, you need a specific kind of engineered aluminum microstructure via grain refinement. But the way they design this aesthetic aluminum is counter-productive to heat dissipation. Thermal management while also making it look cool … that’s 100 percent a materials science problem,” he explained.

Caretta believes these more relatable applications of problem solving can be the answer to inspiring a younger generation of materials engineers to take interest in the field, and, in turn, engineer more energy-efficient materials to help tackle large-scale technological challenges.

His career path took him from Minnesota to MIT for a doctorate, after considering the top materials programs in the world. “There were three elite professors (at MIT) who studied magnets — a subject I barely knew anything about, so I figured there had to be something to it,” he said. He would join Geoffrey Beach’s Spin Dynamics group at MIT to study nanoscale magnetic materials and devices. Historically, the only way to manipulate a magnet is by using the energy-expensive stray field of another magnet. Beach’s group does it differently by using the spins of electrical currents, voltages, and light to engineer low-power memory and logic.

Following that, Caretta headed to California for a postdoctoral appointment in a new field, and was awarded the prestigious Ford Foundation Postdoctoral Fellowship and the UC President’s Postdoctoral Fellowship. “I think there are two general approaches to postdocs: dive deeper into what you know, or do something different. I chose the latter,” he said. “It was very strategic, I wanted to join a group where I could learn to make materials more precisely. Typically, in the field of spintronics, most people use one sort of materials synthesis technique called sputtering. You can make only a limited subset of materials using that technique. That limited subset is useful, but there are a variety of other functionalities, materials properties, chemistries, and performance enhancements that you can bring into spintronics or other types of on-chip computing by integrating new materials. I wanted to learn how to synthesize those materials.”

Now known in engineering circles as a “materials grower” himself, Caretta comes to Brown to fill a niche for the University with his ability to synthesize material that no one else can make. “My personal motivation with these materials is energy. When you think about computation, memory, logic, and data storage, typically the first priorities that come to mind are speed and density. But really, the main challenge today is energy efficiency. New computing paradigms like artificial intelligence, machine learning, big data, and neuromorphic computing are extremely power-intensive types of computational techniques and processes. So much so, it is actually predicted that within the next few decades, approximately 30 percent of the world’s energy consumption will be from computing. We can either burn more coal to match that, or, like what (Professor) Nitin (Padture) is doing, design new ways to extract or produce energy more efficiently. Alternatively, we could just change how much energy it takes to do a computation. A lot of the material systems I try to design are for energy-efficient computing. How can we design a material property, or a set of materials or interfaces, that does a compute or memory process more efficiently? It’s not just about new computational architectures, but fundamentally, what are the materials that can allow for that, and how do you achieve that level of control over a material’s properties?

“ Brown is, for a materials science analogy, at a phase transition. There are some significant changes that will happen over the next few years, in terms of growth in research, growth in faculty, and changing what the curriculum looks like – that’s an exciting place to be ... Having an impact on what that phase transition looks like was a big attractor for me to come to Brown. ”

“There’s no one who does exactly what I do here at Brown, so I think what I do is highly valued. There are people in chemistry, physics, and engineering all looking at similar problems, but I offer a new perspective on how to solve these problems. The exciting part is that I can align my research with fields I didn’t even imagine it would fit into. A nice thing about engineering and physics at Brown is that they’re in the same building. It’s very easy for me to go up a floor and talk to (Physics Professor) Gang Xiao, or down a couple floors to talk to (Professor) Alex (Zaslavsky) in Engineering.

“The materials I study are not just interesting to me, they are interesting to a lot of people at Brown, and that can breed exciting research and collaboration — with robust impact.

“Brown is, for a materials science analogy, at a phase transition. There are some significant changes that will happen over the next few years, in terms of growth in research, growth in faculty, and changing what the curriculum looks like – that’s an exciting place to be. The phase transition is always an exciting place to be. Having an impact on what that phase transition looks like was a big attractor for me to come to Brown,” he said.

“The other thing that attracted me to Brown is that, while at most universities, the bottom line for a professor is typically research out and dollars in, at Brown there seems to be a third bottom line: student success. The quality of students that are produced is important and the education they get is very important — I could sense that from the beginning. Most other places, the topics of conversation are mainly focused on grants and papers. Including student success as a priority is a more holistic approach for a place that is a research institution and an educational institution.”

Caretta will be teaching a new graduate-level course on electronic and magnetic materials design in the spring, looking at materials at the heterostructural level. In it, students will have an opportunity to either design their own device or take an existing device and improve upon it, with the overarching goal of perceiving the world through a materials lens. The following fall, he is slated to teach ENGN 0041, “which I’m very excited about,” he said. “Maybe more excited about it than teaching my own course because that’s where you really get to shape a student’s mind.”

He envisions his lab will include some of the best academic thin-film deposition facilities in New England. When complete, it will have four different deposition systems, or four different ways to make atomically precise materials in the lab, providing a breadth of versatility. With these systems, the lab can span materials classes and make an array of materials. The other half of the lab is designed for characterization and implementation.

“We make materials, we characterize those materials, we turn them into something useful at the nanoscale,” he said.

As for filling the lab with students, Caretta says he has one graduate student arriving this spring, two more next fall, is actively looking for a postdoc and “would like as many undergrads as I can get.” He continued, “I think there’s something to be said about introducing the concept of materials science to people who don’t know about it. It’s my job to make it sound interesting to them and attract them to the field. The more undergraduates we get, the better.”