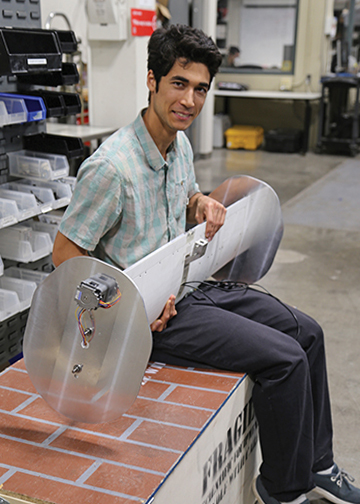

Wind tunnel tests of a trailing edge flap moving vertically on a wind turbine blade was the main focus of Alex Koh-Bell’s senior research project - a project which took two semesters and included multiple iterations in CAD, machining and 3D printing to put together a test rig, programming in MATLAB to control the motors of the test rig, and collecting large quantities of data to extract the lift and drag forces experienced by the controlled wind turbine blade. Koh-Bell, a mechanical engineer, landed on this project in Professor Kenny Breuer’s lab because of its relation to renewable and clean energy, and it was during an intro to fluid mechanics class that a general announcement about the projects available in the Breuer Lab caught his eye. The rest of his story took flight from there.

“Most of what I was doing for this project was running experiments in the wind tunnel to test a specific mechanism for wind turbine blades. I was measuring the forces experienced by the blade when wind blows, simulating what would happen in a real wind-turbine setting,” Koh-Bell explains. “The mechanism is a small flap that moves up and down on the end of the blade. That small flap offers adjustability in the system which is quicker and easier than moving the entire turbine blade. The blade is typically very long and heavy. I helped measure forces in the wind tunnel to understand the effect of that flap.”

In a real world environment, neither the wind nor flow is controllable, so designing the perfect blade shape for every potential wind condition, or at least making the blade adaptable to differing conditions, has been a topic of interest for some time. The design, fabrication and testing of a wind tunnel model based on the geometry of a commonly-used wind turbine blade and the changes in aerodynamic performance of the wing due to the deployment of an active Gurney flap is a project of the Breuer Lab and Ph.D. candidate Siyang Hao. The project originated from Arctura, Inc., a local technology innovation company focused on wind energy solutions. The flap is located near the trailing edge of the wing on the pressure surface and is raised and lowered to modulate aerodynamic performance.

Koh-Bell’s efforts were rewarded not only with his senior thesis, but also a Doris M. and Norman T. Halpin prize of seed money to support the innovative and interdisciplinary project, along with a gift to the research facility to assist in the testing and presentation of the final results. Koh-Bell traveled with Hao to Phoenix last fall to present the topic at the 74th Annual Meeting of the American Physical Society’s Division of Fluid Dynamics. There is the potential for a future conference to present more recent results, although Koh-Bell will be handing off his research to other lab members to pick up where he left off. Soon after graduation, he began work at a startup fusion company based in the Seattle area.

“I was drawn to this project because I could see what was going on, and I tend to enjoy experimental projects more than theoretical or computer-based research,” Koh-Bell said. “Why I wanted this one, in particular, was because it was a renewable energy project. Clean energy, more generally, is what I want to work on.” A class taught by Breuer (ENGN 1700-Fluid Mechanics of Aerospace and Energy Systems) taken in the fall offered much more context for the project, and allowed Koh-Bell to further the extrapolations from the data he collected.

The California native said his specific interest in engineering and environmental applications evolved after a summer research stint in a lab at UC Berkeley. His other interest was in biology, and luckily many of the early requirements to his Brown degree overlapped. “I finally made the decision (to choose engineering) when I found a position in a lab that was working on biology applications - mainly things like tissue preservation at low temperatures and preserving organs needed for transplant,” he said. “Working with those people really convinced me to stick with engineering, just seeing the process, the ability to concretely get things done that can have a substantial impact - that was the main takeaway I had from that summer. It was a mechanical engineering lab doing work intended for biomedical applications, and I realized mechanical engineering doesn’t prohibit me from working in a BME field, from any field really. To me, for my goals, it just offered greater flexibility.”

Koh-Bell, who also served as a Teaching Assistant for ENGN 0040 - Dynamics and Vibrations, has a collegiate resume showing he understands both flexibility and focus. As a member of the engineering honor society Tau Beta Pi, he took home the Outstanding Mechanical Engineering award at Commencement. He is as comfortable discussing World Music Ensemble, as he is on basketball courts or soccer pitches. He can talk about Brown Space Engineering, piano lessons, or climate solutions. “I chose Brown four years ago not knowing that I wanted to study engineering, but the open curriculum ended up being really helpful for me, even more important than I thought it would be,” he said. It was a choice that allowed him to soar.