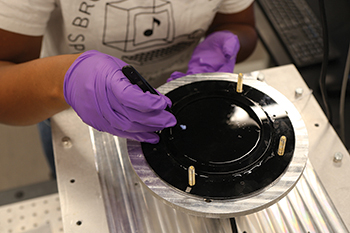

Lewis’ summer project began with investigating capillary attractions with magnetic repulsions, playing with different magnet strengths and different sizes of discs to balance the attraction and finding that sweet spot of equilibrium distance. She was tackling a question that had been explored on a significantly smaller scale many times, but replicating that experience on a larger scale to make it more accessible and easier to perform in more labs is what resonated so strongly with the junior from Washington, D.C.

“Not having to use microscopes, but using things that are more commonly found in labs like 3D printing and a simple molding process, using materials you can find at craft stores, that’s where this project began,” Lewis explains. “Then it opened the door for wider applications, because basically this casting process has the potential to be applied to so much.”

“Not having to use microscopes, but using things that are more commonly found in labs like 3D printing and a simple molding process, using materials you can find at craft stores, that’s where this project began,” Lewis explains. “Then it opened the door for wider applications, because basically this casting process has the potential to be applied to so much.”

Thus far, the process also seems to be precise, a key component in making it usable for others in a laboratory setting. “When you try to make small parts with laser cutters you run into the issue of the laser not being as exact as you need it to be, especially on the edges, and when you’re looking at the contact angle, or where the object sits on the fluid, this is very important and will determine how effective your process is,” she explained. “Right now I’m looking at other projects that have taken place in the lab, and trying to replicate those results using this casting process.”

One such project is that of recent graduate Ian Ho ’21, who manufactured capillary surfers in the lab in an effort to study the propulsion of solid particles by self-generated wave fields on the surface of a vibrating liquid bath. “Ian had found if you put two surfers on a vibrating bath, they can feel each other’s movements, and kind of get locked in with each other,” Lewis said. “He used the laser cutters to manufacture the surfers but it was really hard to get the precision they needed for it. So if they made 20 surfers, only about five would be able to work for the project.

“This (casting method) has the potential to be a super accessible and easy to use process to accelerate the investigation of some of these research questions.

image and data acquisition

“I think that’s something that I really love about the Harris Lab,” she said. “There is a really big emphasis on how we can study things in a more accessible way. Oftentimes that means making things bigger, so you don’t need a microscope or such precise equipment, and sometimes it means using materials, like crafting items, you wouldn’t think of to use in a lab. So that helps put my research into perspective. If this works, then people will be able to study things they haven’t been able to before. Which is really encouraging.”

For Lewis, her affiliation with Assistant Professor Dan Harris’ lab happened by chance, but feels like preordained fate. As a high school student, she was active in social justice initiatives for children and worked as a camp counselor, so naturally once she settled into life on College Hill she became immediately involved in BEAM (Brown Elementary Afterschool Mentoring), as a Residential Peer Leader, and as a peer counselor in the Sarah Doyle Center. When she saw the posting for the lab, it was a much simpler plan than trying to write another line on her resume. “Get a job, make some money. That’s all I thought,” she said, “but when I interviewed, Professor Harris explained that I’d have my own project and that I’d be the expert on it, and after that, I realized I really wanted it. I was lucky enough to get it.

“The lab aligns with the kind of work I like to do in the community. The idea that the work I’m doing could be taken up by a wide range of students, including college students who need a take home lab. That kind of informs my drive within the lab.”

“I’m now a Brown Design Workshop mentor with ENGN 30 (Introduction to Engineering), which I’m very excited about,” Lewis said. “Being a first-year is scary, but also engineering is scary, and I feel like my BDW mentor was someone I really turned to my freshman year for insight on all things engineering, not just the class or how to use the laser cutter. .

“Right now I’m really hands-on, focused on this method of production. I’m having to get creative with little problems here and there, and thinking outside the box. I think it’s so fun and love being able to come up with unconventional ways to solve problems.”

It just may be that her crafty successes of this summer lead directly to another person’s scientific breakthrough.