Almost every weekday, in the open spaces of the windowed and brightly lit lab on the second floor of the Engineering Research Center, Lopez, a senior, combines a graphene oxide suspension with other chemicals and pipettes the result into a molding sheet, which he then sets aside to dry for two days. The process is repeated three more times throughout the week, until he is left with one layered graphene oxide (GO) film plastered to the mold. From there, he carefully removes the film and takes the mass of each one. The GO film that passes quality control is then sandwiched between plates and placed into an oven at 250˚C for an hour to induce GO thermal exfoliation, resulting in a final product rGO film.

Almost every weekday, in the open spaces of the windowed and brightly lit lab on the second floor of the Engineering Research Center, Lopez, a senior, combines a graphene oxide suspension with other chemicals and pipettes the result into a molding sheet, which he then sets aside to dry for two days. The process is repeated three more times throughout the week, until he is left with one layered graphene oxide (GO) film plastered to the mold. From there, he carefully removes the film and takes the mass of each one. The GO film that passes quality control is then sandwiched between plates and placed into an oven at 250˚C for an hour to induce GO thermal exfoliation, resulting in a final product rGO film.

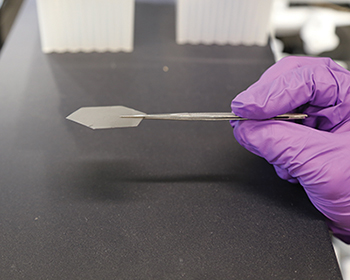

After exfoliation, the rGO film is carefully scraped off the plate by Lopez, producing a delicate sheet that will be further examined. These rGO films are not only used by Lopez and his lab mates, but also by other research groups in the ERC and other universities. He has been doing this for quite some time now, and as his academic background caught up to speed with his reliable handiwork and other critical lab skills, it was a natural fit for him to take the sheets further and begin fabricating rGO films for testing indoor air pollutants.

“The rGO film I’m making is able to pick up some of the indoor air pollutants listed in the EPA’s top list of contaminants we might be exposed to, and then, once extracted, release those contaminants for testing,” Lopez explained. “A goal I’m hoping to achieve is to make these rGO sheets into a form that’s a little less delicate, because right now they are a bit brittle. Our long term aim is to produce these films in a way that would be wearable - like a patch. So when someone leaves the room where they spent quite a few hours, then that patch could be removed and the contaminants extracted for identification.”

Thanks to a stipend from the DiMase fund, Lopez spent the summer preparing rGO films for passive air sampling and modeled the thermal exfoliation process. Work involved isolating constants for the model, and developing his own equations to learn more. “This was a little easier said than done,” Lopez said. “Because most of the molecular components go hand-in-hand, so I’d say most of the summer was spent thinking of ways that I could test just one chemical reaction. The research has been broken down to at least six different experiments, and all of it had to be analyzed on computer code and I’ve now gotten a clean final model.” He is hopeful to turn his data and findings into an honors thesis.

Lopez, who comes from a family of lawyers, credits Senior Engineering Lecturer Indrek Külaots with the inspiration to declare chemical engineering as his concentration. “After my first year at Brown, I wasn’t sure what I wanted to do. And no one in my family has studied STEM or anything like that, so I wasn’t sure what I could do with it. That’s when I met Professor Külaots to talk about class load and things of that sort. And I really liked his style. He’s one of those professors that is very intelligent, but he also understands students, and so it was really nice to be in his class. I decided to try to work in his lab, and that’s how I first got involved.

“There have been a few classes at Brown that really stand out in my time here, but the one that stands out the most was my first year. I was in the hardest math class I was allowed to take, and that class beat me down so badly. It was the most difficult class I’ve ever taken. Some of the assignments were so time consuming, and I realized quickly that my confidence was misplaced and that I actually had to relearn things, including humility, and start trying to actually gain an understanding of these concepts. It taught me a lot about cooperation, because you are allowed to work together on the homework. As a freshman going into engineering, you don’t think you need that. But by the end, it became so necessary to make some friends in class and learn to work together that I credit that one class as the single thing that really got me into the attitude of Brown - which is you have to cooperate, and you have to work as a team.”

Although still not sure what direction his future may go, Lopez knows there are plenty of options. “Most of the people I’ve worked with (in the lab) were seniors last year.. Some are in graduate school, some in industry, some have become finance workers, and then some took gap years. The flexibility has been nice to determine what I wanted to do here, but I suppose this senior year is where I’ll decide what happens next.