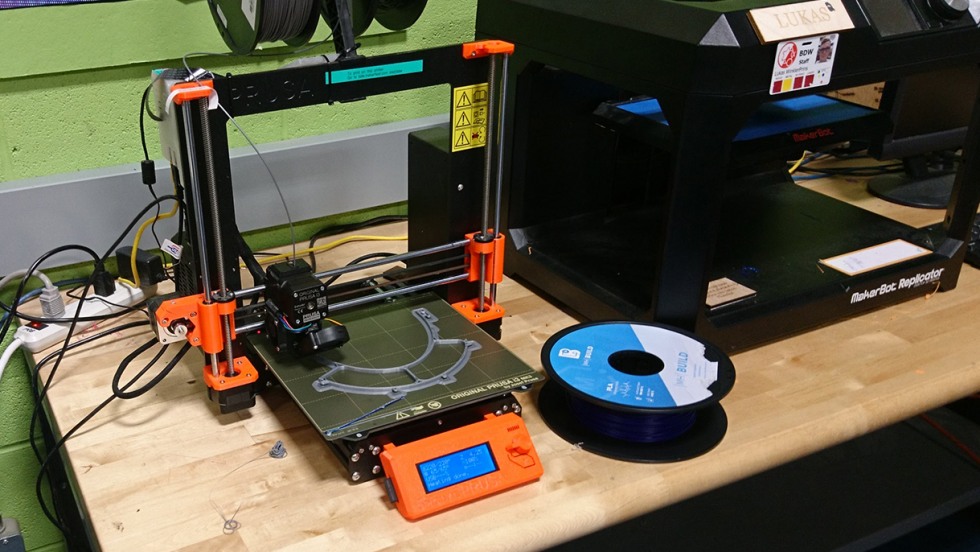

With the resources of the Brown Design Workshop at hand, BDW Director and Engineering Senior Lecturer Chris Bull has been balancing the production of molds for filtered silicone face masks, and prototypes of first responder respirator shields for Rhode Island Hospital, along with face shield components created for a local connection, who happens to be an engineering alumnus. The BDW offers a range of tools and equipment, including consumer-grade 3D printers and a 32-by-18-inch laser cutter, and enough supplies for several prototyped designs and fabrication of urgent medical needs. A one-man show in what is usually a busy makerspace full of students, Bull is doing his best to safely spread the work and word of how others can get involved.

With the resources of the Brown Design Workshop at hand, BDW Director and Engineering Senior Lecturer Chris Bull has been balancing the production of molds for filtered silicone face masks, and prototypes of first responder respirator shields for Rhode Island Hospital, along with face shield components created for a local connection, who happens to be an engineering alumnus. The BDW offers a range of tools and equipment, including consumer-grade 3D printers and a 32-by-18-inch laser cutter, and enough supplies for several prototyped designs and fabrication of urgent medical needs. A one-man show in what is usually a busy makerspace full of students, Bull is doing his best to safely spread the work and word of how others can get involved.

Conversations on COVID: Chris Bull engineers equipment to aid in crisis

Q: How did you get involved with making these different prototypes and shields?

For the facemask molds and the respirator shields, it was Dr. Albert Woo, from the Med School faculty, who coordinated University efforts with the Lifespan side. He reached out to local groups who have 3D printers. Dr. Woo is the Rhode Island Hospital liaison in charge of the group called the Rhode Island 3D Printing Collective and before this, part of his work was figuring out how 3D printers were useful in medical settings. He has a lot of experience in using 3D printers to print models that surgeons could use to guide surgery. He’s done a fair amount of orthopaedic stuff, like bone models, that sort of thing. Then this (COVID-19) came upon us, and he was leveraging what resources he had to get the emergency equipment needed. We started with making prototypes of simple face shields.

Q: Who are some of the creative/building/communities at Brown who responded to this endeavor?

I know (Lead Educational Media Developer, CIS) Kelly Egan and (Instructional Media Specialist, CIS) Leo Selvaggio, of Brown’s multimedia lab in the Granoff Center are doing some 3D printing. So they did some shields early on. We did some. There are open source designs out there, and I don’t know how I even really got into the email loop on this, but it was “Can you do this?” and then we needed to negotiate with EHS (Environment, Health, and Safety) officers to say it was okay for even one person to be in the space (the BDW is located in Prince Lab). Then it took a few days to have a protocol that they were happy with for using the space.

Q: What happened with the initial project?

RIH found a manufacturer that could give them 8,500 shields very quickly. So then Dr. Woo turned his attention to a couple of other items, a mold for the mask, which has a filter, and the respirator shields, which became a much higher priority.

Q: Where are you in this process?

Right now what we’re doing is printing molds so that we can later cast silicone into the molds to make them. When I say we, I mean we have one printer working on a first responder face shield project from another connection and one printer working on the mold. Hopefully we’ll be able to bring a couple more printers online to do both. I’m trying to make it so other people can participate in some way, and some of the printers we have are accessible remotely. (Senior biomedical engineer and BDW manager) Eric DuBois is doing much of the 3D prepping from wherever he is. The printers have cameras on them so he can do that remotely.

The respirator face shield project from RIH involves laser cutting. Respirators are soft helmets that first responders might wear that have a blower that makes it so nothing can enter. It is part of a “suit.” The suits are reusable, but they want to replace or sterilize the face shields, so I’ve reverse-engineered existing shields to adapt it to the laser cutting process. So today I will put together a few of those that they can then see how well they work in the respirator units.

Play

Play

Q: What other projects are you are working on?

We have an engineering alum (Adam Standley ’07, Sc.MIME ’08) who got in touch with Professor Allan Bower, who connected him with me. And so I connected with Adam (founder of Arista Solutions, LLC in Boston) and we figured out what we could do. Adam has an open source design, and has put together a group of regional engineers to supply face shields to local hospitals. The strategy is to have a highly flexible supply chain using locally available materials. One of those supply routes involves community-sourced 3D prints, and then Adam has set up an assembly line at his company's laboratory.

Q: What is the timeline on this?

We had laser cut some of the shields for him, and we’ve been 3D printing the frames. We’ve already made one delivery of shields and frames and they will be trying to assemble 1,000 of these by Friday. He delivered 200 face shields on Monday to Mount Auburn Hospital (in Cambridge) and they were delighted to get them. He’s connected to the right people to get what is made in the hands of those that need them.

Q: Utilizing connections and available equipment seems like something you’re doing a lot of right now. Is that safe to say?

I’ve been trying to spread the word on that. For instance, I was talking to (mechanical engineer) Isaku Kamada ’17 this morning, and he has a 3D printer at home, so I sent him the (open-sourced) files and he’ll make some and send them to Adam. So many of our students and alumni, really talented individuals, are asking how they can help, so I’m looking for ways to get them involved.

Q: Why did you want to do this?

Our normal ways of feeling productive, or useful, have been, for a lot of people, taken away. I think everybody would like to feel like they can make some contribution to making things better, and there are so many restrictions now in terms of what you can do. I think everyone looks for an opportunity like that. And then I guess I’ve been doing this long enough that it’s kind of intuitive how it might go together, and what you might change to make things better and all that sort of stuff.

Q: You say you’ve been doing this long enough, it’s intuitive. Can you relate this to anything that has happened before in a similar situation?

I think the relation is translating something you see into something you can make. It’s being able to look at something and then say, ‘Given what I have, how would I produce it? And how would I do it in a way that doesn’t cost much? Or uses materials that are easily available?’ -whatever those constraints may be. There are lots of people with 3D printers and abilities who want to physically do stuff. And right now, how they get made doesn’t make any difference. The only thing that matters is do they work? And are they available?