Brown junior Ian Ho's penchant for building things has made him an integral part of a School of Engineering research lab, an experience helping to shape his future.

Daniel Harris always has an eye out for a particular type of student to work in his fluid dynamics lab in Brown's School of Engineering.

"I look for creative people who can build stuff, iterate on their designs and work out ideas," said Harris, an assistant professor. "They don't need to know all the fluid mechanics right away — we can teach them that. But I want people who can make things."

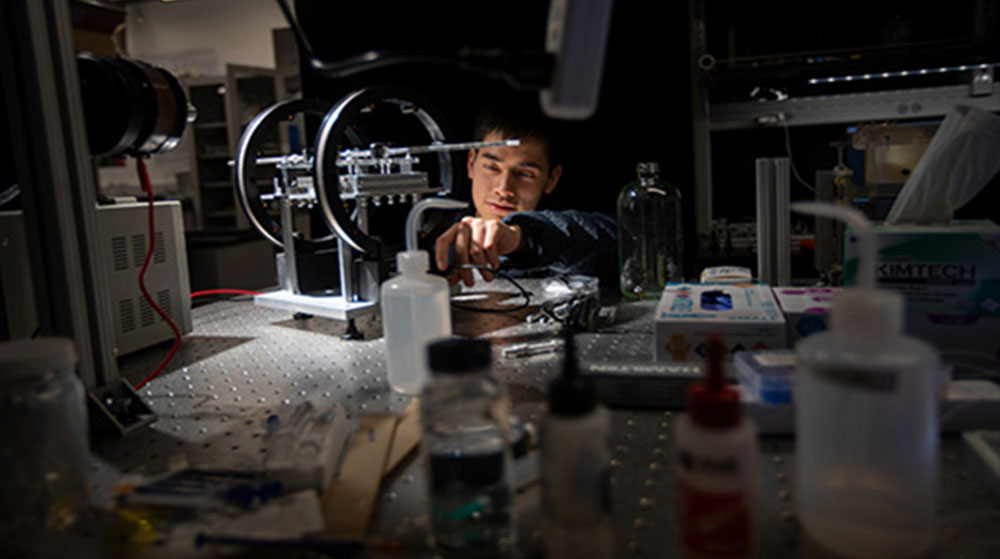

Harris found just such a student in Ian Ho, a junior engineering concentrator at Brown who joined the lab as a first-year student. Over the past two years, Ho has made himself an integral part of the lab, Harris says. Most recently, Ho built a device that made it possible to measure forces that had never been measured before and was the lead author on a journal article describing the work.

"It's not particularly common for a freshman to have a research position in a lab," Harris said. "But Ian has a crucial role here. And he really took the lead to build the device that made this latest paper possible."

Ho says the work in the lab has been the cornerstone of his Brown experience.

"I've learned a lot in both designing and conducting custom laboratory experiments," Ho said. "In addition to Professor Harris' mentorship, I find these experiences to be really invaluable and something I wouldn't normally receive from coursework."

The paper that Ho coauthored explores a phenomenon that many people see at the breakfast table every morning — the "Cheerios effect." It's the observation that the last few bits of cereal in the bowl tend to cluster together on the surface of the milk, rather than dispersing randomly. Scientists have a good theoretical idea of why this happens, but no one had actually measured the forces involved in the phenomenon at this scale. Understanding those forces could be useful in the self-assembly of micro-machines or the design of small aquatic robots.

But there was no existing apparatus capable of making the measurements, so Ho had to build one himself.

The device he built consists of a small tub of water encircled by electrical coils. Two Cheerio-sized plastic disks, one of which is fitted with a magnet, are placed on the surface of the water. An electrical current running through the coils creates a magnetic field, which pulls the magnetized disk away while the other is held in place. By measuring the intensity of the magnetic field at the instant the disks begin moving away from each other, the researchers could determine the amount of attractive force between them.

Because the of the nature of the experiment, most of the device needed to be custom-fabricated, Ho says.

"You can buy some of these components premade, but the reason we fabricated everything ourselves is that it has to be non-ferromagnetic," Ho said. "Ferromagnetic materials can distort the magnetic field, so we couldn't use them."

Using 3D printers, laser cutters and other tools available in the Harris Lab and the Brown Design Workshop, a makerspace open to all students, Ho was able to come up with a prototype. With some trial and error, he eventually had a finished device that could make the measurements.

There were more than a few challenges along the way. The forces the device measures are on the order of the weight of a mosquito, so Ho had to take care that the device itself wouldn't interfere with the measurements. A particular source of frustration, Ho said, were two tiny rods that hold the disks in place until the measurement is made.

"Initially the surfaces our rods were kind of rough," Ho said. "I didn't sand them properly and they were affecting our force measurements. So I had to go back and get rid of any imperfections."

Harris says that Ho's fabrication work was integral to the project.

"We had this vague conceptual idea to make this measurement using magnets," Harris said. "But someone actually had to build the thing, and that's what Ian did."

The work ultimately paid off for all involved. The scientific community got a first-of-its-kind force measurement that will be useful in the development of microscale machines. Ho got a ton of design and research experience and a first-authored paper in a prestigious journal to boot. He says his lab experience has been pivotal in helping him think about what direction to pursue after earning his bachelor's degree.

"My experience in the Harris lab has informed me that I really enjoy research, and I hope to continue learning and building on my past experiences by pursuing a Ph.D. after graduation," he said.