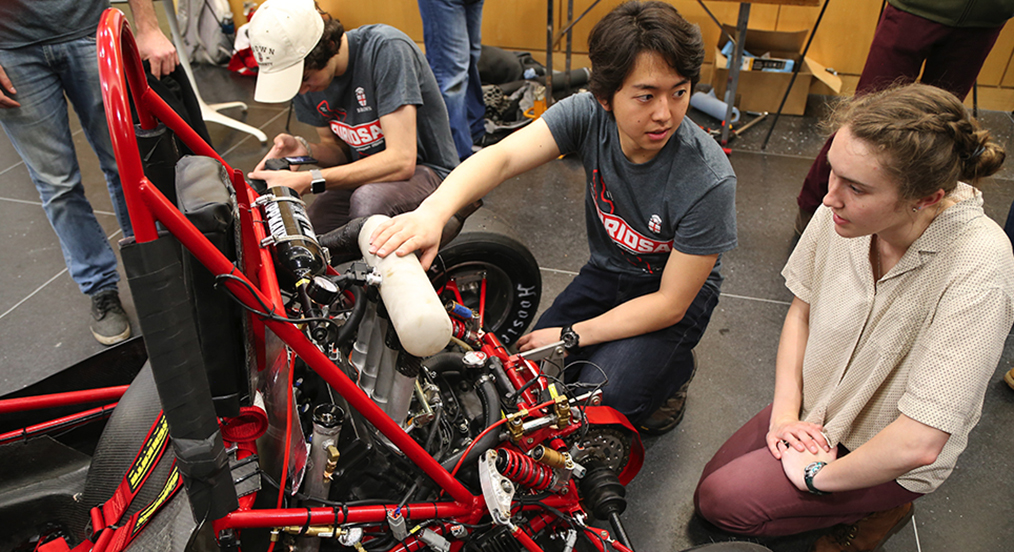

Co-Captain Isaku Kamada '17 describing the new 3D-printed intake design to Erin Cole '19.

The Brown Formula Racing team revealed the latest iteration of the Formula SAE racing car, Rhode Warrior, to the public on Wednesday in the lobby of Barus & Holley. This marks the earliest the car has been ready to showcase to the public, at least in the last four years, and was an opportunity for team members to be on hand to answer questions, as well as show off the extraordinary effort put forth by the group.

This year's car has a new body paint job, introducing racing stripes for the first time, as well as several internal changes. The chassis remains red, as always, "because red makes us go faster," said Kelsey Sandquist '17, quoting a familiar refrain from the car team's past. Sandquist is one of three captains for this year's design, along with Isaku Kamada '17 and Philip Mathieu '17. All agreed that the internal deadline to show it off in Barus and Holley was really a driving force in the preparation and design that took place during the academic year.

"Reliability was big for us," Sandquist said. "Last year we ended up destroying two engines due to oil deprivation." The oil system change was probably the biggest change of the internal design, which moved the center of gravity, forcing other compensations along the way. The switch to a wet sump oil system was led by Paul Friedman '18, shifting the engine further up in the car, which required the team to change the intake to an over the shoulder design. Electronics lead Jaekyung Song '17 improved the driver feedback by designing a dedicated driver feedback PCB board and waterproof enclosure that is both more visible and adjustable for the driver.

Additionally there has been a change in the frame, using a series of tubes the team has dubbed "Kevin Tubes", after teammate Kevin Eve '18. Eve took on the task of testing last year's frame in order to make improvements, producing a more stiff and rigid design for the 2017 competition. The 22 design leads worked tirelessly over the past year to make the car possible, and there was a high level of involvement by new team members this year.

"I'm proud to say we used the BDW a lot," Sandquist said, referring to the Brown Design Workshop, an engineering makerspace open to all Brown and RISD students with the intention of making the disciplines of creation and design within the School of Engineering more collaborative, open, flexible and accessible to all parts of campus. Kamada agreed. "A few of our parts were 3D printed, including the handles and levers, all things the driver interacts with. The latest CNC mills and lathes in the BDW were vital to manufacturing our complicated components and an extremely valuable learning tool for machining knowledge," he said. Once the parts were made in Prince Labs, the welding, composites work, and vehicle assembly all took place at Tockwotton Studio, about a mile south of campus.

The overarching goal of the team this year is to finish the endurance race with confidence. This motivated all of the design changes in favor of a more reliable oil system, more weatherproof electronics components, and also created a focus on reverse compatibility. Being able to use a previous year's component as a backup (should one from this year fail) means that major changes were minimized in favor of sticking to an ambitious manufacture & testing schedule. The additional testing time allowed the team to collect hours of data on vehicle performance to ensure that every system will perform at its best on the track.

Rhode Warrior, complete with red racing stripes on the carbon fiber body work designed by Body-lead Bharath Kayyar '19.

The competition itself includes a field of 120 teams, judged by the top voices in the automotive industry. Teams are awarded points based on their performance in design cost, business presentation, and four dynamic events: acceleration, skid-pad, autocross, and a 22-km endurance race. The event will be held in Brooklyn, Mich. at the Michigan International Speedway, May 10-13. The car itself must conform to 180 pages of rules, or the "formula", which are geared toward safety and outer limits on power and force. Beyond that is where the team's creativity and engineering ideas came into play.

Rhode Warrior marks the 21st car Brown has entered in the Formula SAE competition, and past teams have finished as high as sixth place. Alumni relationships remain strong with this group, as recent graduates David Brown '11, Brennan MacInnes '16, James Dilling '16, Thanin Kovitchindachai '16 and Graham Keeth '16 all found their way back to the BDW to offer suggestions and feedback on this year's model. Christine Herrmann '16 also checked in virtually. "We really want to thank our wonderful alumni for always responding to our panicked emails, our faculty advisor Chris Bull for his patience with us, and the amazing staff of Prince Lab and the JEPIS machine shop," Kamada said. "We wouldn't be here without their support."

Brown Formula Racing, with more than 40 team members, is the largest competitive student group in Brown Engineering.